Beyond the Pole: 3 Fatal Electrical Connection Traps 90% of Engineers Overlook in Solar Street Light Procurement

- coco wang

- 2025年11月1日

- 讀畢需時 6 分鐘

Introduction: The Silent Project Killer Hiding in Plain Sight

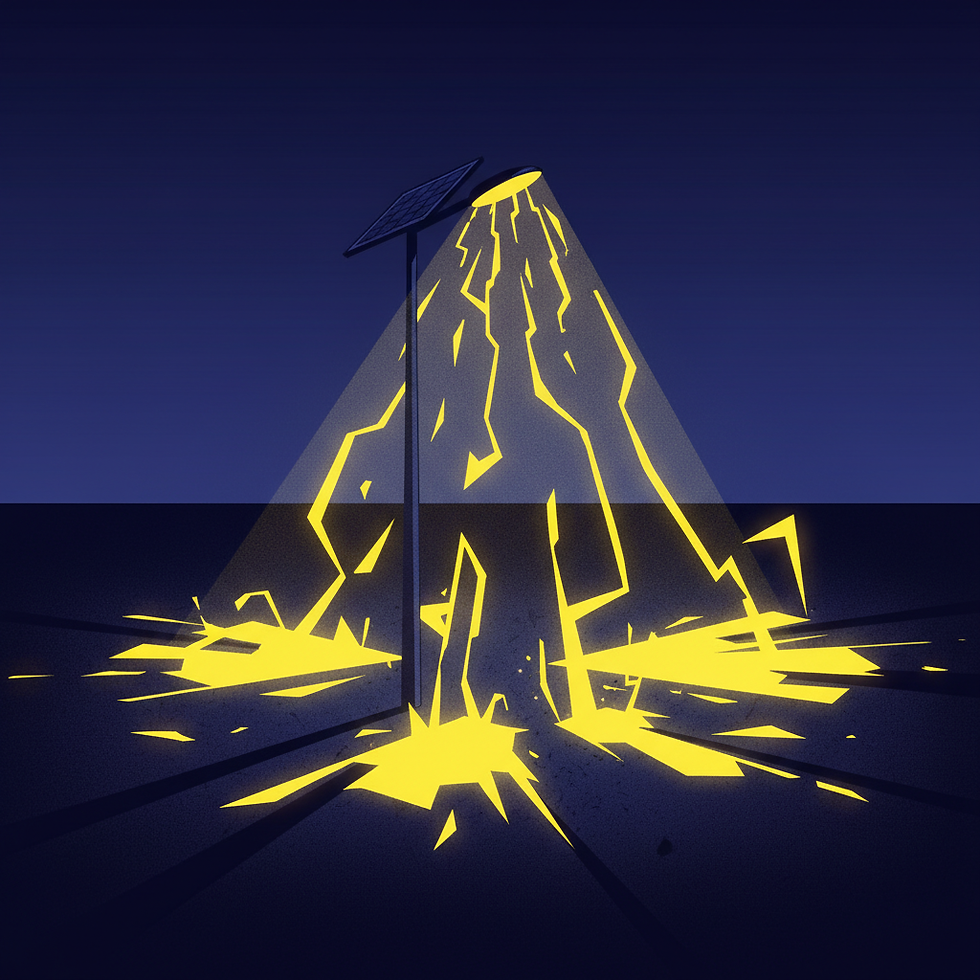

A multi-million dollar municipal lighting project, delivered on time and on budget. Six months later, intermittent failures begin. By the first anniversary, nearly 15% of the lights are dead. The culprit isn't the high-performance LED chips, the robust solar panels, or the advanced lithium batteries. It's a series of failures originating from components that cost less than a cup of coffee: the electrical connectors and wiring. This scenario is not hypothetical; it's a costly reality for countless project managers and engineers who focus on the macro components while overlooking the microscopic details of the electrical system.

In the world of solar street lighting, the conversation is dominated by lumens, battery cycles, and panel efficiency. Yet, the entire system's longevity and reliability are fundamentally tethered by its electrical nervous system. Ignoring the nuances of electrical connections is not just a technical oversight; it's a strategic blunder that invites catastrophic, system-wide failure. This article moves beyond the spec sheet's main features to uncover the three most common and fatal electrical traps that even seasoned professionals can fall into, providing a framework to ensure your project's electrical integrity is rock-solid from day one.

Trap 1: The Underestimated Threat of Flawed Grounding in Off-Grid Systems

In conventional grid-tied systems, grounding is a well-understood, mandatory practice. However, in standalone, off-grid solar lighting, it's often dangerously minimized or misunderstood. The assumption that "low voltage means low risk" is a primary source of failure.

The Phantom Menace of Static Discharge and Surges: A solar street light is essentially an isolated metal mast, a perfect lightning rod. Without a dedicated and properly installed grounding system, a nearby lightning strike can induce a massive voltage surge. This transient voltage instantly destroys sensitive electronics like the MPPT controller and LED driver, rendering the entire unit useless. It's not just about direct hits; electrostatic discharge (ESD) built up from wind and dust can be equally damaging over time.

Creating a Stable Electrical Reference Point: For an MPPT controller to accurately track the maximum power point and for an LED driver to deliver stable current, they require a stable zero-volt reference. Improper or non-existent grounding can lead to a floating ground, causing erratic controller behavior, flickering lights, and premature component failure. From an engineer's perspective, it's like trying to make precise measurements on a ship tossed in a storm?the lack of a stable reference point makes accuracy impossible.

The Hidden Cost of Negligence: A project manager must see grounding not as an expense, but as insurance. The cost of deploying a proper grounding rod and copper wiring is negligible compared to the cost of dispatching a crew with a bucket truck to diagnose and replace a fried controller on a single pole, let alone dozens. Quantitatively, a $50 grounding installation can prevent a $500 repair and the associated reputational damage from a dark, unsafe street.

Trap 2: The "Good Enough" Fallacy in Cable and Connector Selection

Choosing underspecified cables and connectors is perhaps the most common trap. It's a decision often driven by minor, short-term cost savings that leads to major long-term performance degradation and safety hazards.

Beyond Amps: The Compounding Effect of Voltage Drop: An engineer might correctly size a cable based on the current (Amps) it needs to carry. However, they often forget to calculate for voltage drop over the height of the pole (e.g., 8-12 meters). A 5% voltage drop in a 12V system is 0.6V. This seemingly small loss means the controller receives an inaccurate battery voltage reading, potentially leading to premature low-voltage disconnects. This starves the LED of its required power, reducing lumen output and jeopardizing the lighting standards the project was designed to meet.

The Slow Killers: UV Degradation and Thermal Stress: Standard PVC-insulated cables are not designed for 10+ years of exposure to direct sunlight and extreme temperatures at the top of a pole. UV radiation breaks down the insulation, making it brittle and prone to cracking. This exposes the conductor, creating a short-circuit risk. A professional-grade, UV-resistant, double-insulated photovoltaic (PV) cable is non-negotiable. It's the difference between a system designed to last 3 years and one designed for 15.

Connectors: The Gateway for Water and Corrosion: The single greatest point of failure in many outdoor electrical systems is the connector. Using simple twist-on connectors or, worse, just electrical tape, is a recipe for disaster. Water ingress through capillary action will lead to corrosion at the contact points. This increases resistance, generating heat and causing the connection to fail. For a distributor, selling a system with cheap connectors is selling a future headache. Specifying IP67 or IP68-rated, locking connectors is a critical unique selling proposition (USP) that guarantees long-term reliability for the end-user.

Trap 3: Overlooking the Invisible Enemies of System Integration

The final set of traps involves a failure to think about the electrical system as an integrated whole, susceptible to external and internal interference.

The Myth of Self-Protection: Many assume that controllers have adequate built-in surge protection. While most have some level of transient voltage suppression (TVS), it is often insufficient for the harsh electrical environment of a tall, isolated metal structure. A multi-level protection strategy, including surge protection devices (SPDs) at both the panel input and LED output of the controller, is a hallmark of robust engineering. For a government procurement officer, this is a key differentiator between a compliant product and a truly resilient one.

Electromagnetic Interference (EMI) Cross-Talk: In modern solar lights that may incorporate wireless communication modules (e.g., for smart city networks), the risk of EMI is significant. Poorly shielded cables or a poorly laid-out control box can allow the high-frequency noise from the LED driver to interfere with the communication module, leading to data loss or connection instability. Ensuring components are EMC (Electromagnetic Compatibility) certified is a critical step often missed in the procurement process.

Improper Fuse and Breaker Sizing: Fuses and breakers are the last line of defense, yet their selection is often an afterthought. An oversized fuse will fail to protect the system during a genuine fault condition, allowing catastrophic damage to the battery and controller. An undersized fuse will be prone to nuisance tripping, leading to unnecessary maintenance calls. The fuse must be sized precisely based on the system's maximum continuous current and the short-circuit current potential of the battery, a calculation that requires a deep understanding of the entire system's electrical characteristics.

Conclusion: Adopting a Zero-Compromise Electrical Philosophy

The transition from a mediocre solar lighting project to a world-class installation lies in the details?specifically, in the integrity of its electrical connections. The allure of saving a few dollars on a cable, a connector, or a grounding rod is a siren song that leads directly to the rocks of project failure, budget overruns, and damaged reputations.

To build systems that endure, we must shift our focus with three key upgrades in our procurement philosophy:

From Component-First to System-First: Evaluate every electrical component not in isolation, but on how it contributes to the long-term resilience of the entire integrated system.

From Assumed Compliance to Verified Resilience: Don't just accept a spec sheet. Demand evidence of UV-rated cabling, IP68 connectors, and multi-level surge protection. Ask for the engineering rationale behind their grounding strategy.

From Short-Term Price to Long-Term TCO: Recognize that investing in superior electrical infrastructure is the single most effective way to lower the Total Cost of Ownership (TCO) by drastically reducing future maintenance and replacement costs.

Ultimately, a solar street light is only as strong as its weakest connection. By identifying and avoiding these common but fatal traps, you are not just buying a product; you are investing in a decade or more of guaranteed performance and safety.

Ready to Build a Foundation of Electrical Excellence?

Don't let a small oversight compromise your entire lighting project. If you're ready to move beyond the basics and discuss the critical details that ensure long-term reliability, the expert team at nfsolar is here to help.

Contact us for a no-obligation Project Consultation or for inquiries about our robustly engineered solutions. Let's build lighting systems that last.

Website: www.nfsolar.netEmail: cocowang@novafuture.netWhatsApp: +8613013537907

留言