Built to Last or Doomed to Fail? The Ultimate Guide to Corrosion-Proof Solar Street Lights for Harsh Climates

- coco wang

- 2025年9月20日

- 讀畢需時 6 分鐘

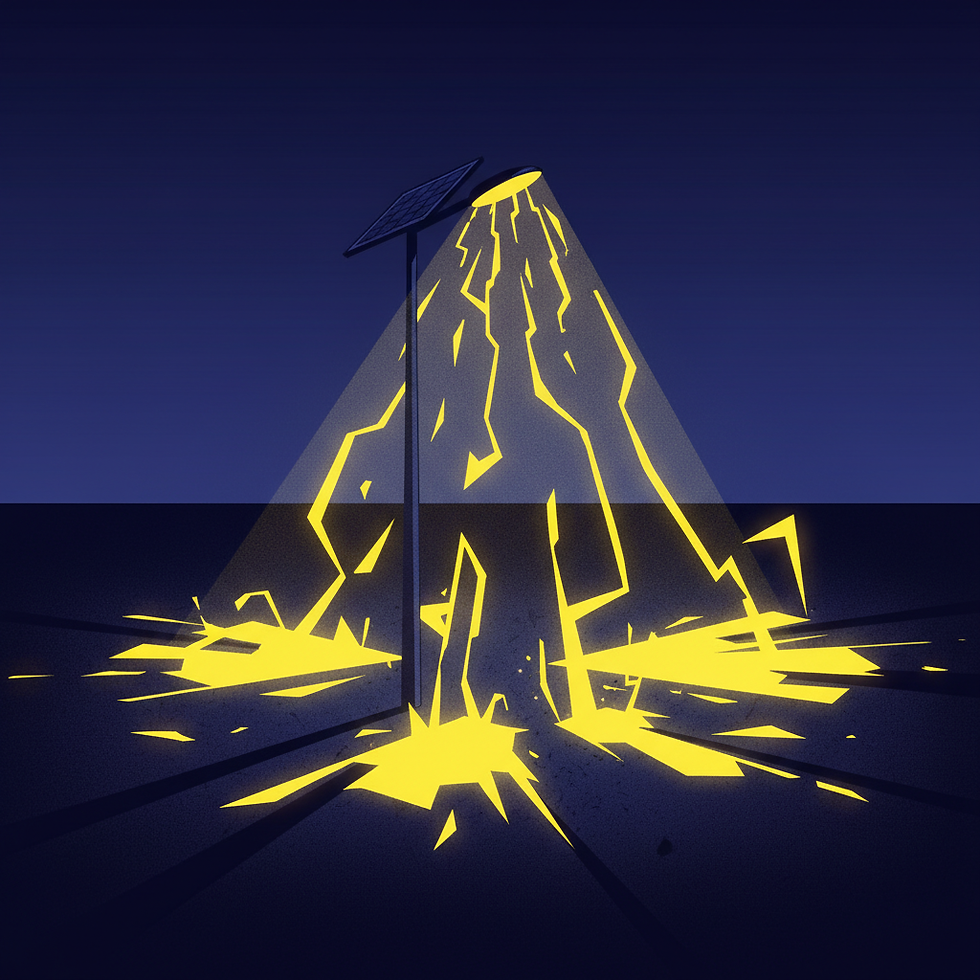

A project manager for a new coastal resort recently shared a nightmare scenario: just 18 months after installation, their brand-new, expensive outdoor solar lights were already showing streaks of rust, with some failing intermittently. The salty sea air, a feature they sold to tourists, had become the silent saboteur of their investment. This isn't an isolated incident; it's a costly lesson learned by municipalities, industrial facility managers, and contractors worldwide.

Standard commercial solar lights, while excellent for typical urban environments, are often woefully unprepared for the relentless assault of extreme conditions. In coastal, high-humidity, or dusty industrial zones, choosing the wrong fixture isn't just a poor choice?it's a predictable failure that leads to spiraling replacement costs, safety hazards, and reputational damage. The assumption that 'outdoor-rated' means 'all-environment-proof' is a dangerous one.

This guide cuts through the marketing noise. We will deconstruct the specific threats posed by harsh environments and reveal the critical engineering and material science that separate a truly resilient solar street light from one that's doomed to fail. It's time to learn how to specify, verify, and procure a solution that is genuinely built to last.

The Invisible Enemies: Deconstructing Environmental Threats

Before you can choose the right armor, you must understand the weapons of your enemy. For an outdoor solar light, these enemies are persistent, corrosive, and often work in concert to accelerate failure.

1. The Salt Fog Assault: A Corrosive Nightmare

For any project near the coast, salt is the primary antagonist. Airborne salinity creates an electrolyte-rich film on every surface. When combined with moisture, it triggers a rapid electrochemical reaction known as galvanic corrosion, especially when dissimilar metals are in contact. This isn't just about unsightly rust; it's a structural cancer that pits and weakens the housing, compromises seals, and ultimately leads to water ingress and catastrophic electronic failure.

2. The Humidity & Condensation Trap: Death from Within

In tropical or high-humidity regions, the air itself is saturated with water. A fixture heats up during operation and cools down at night, causing a pressure differential that makes it 'breathe'. If not perfectly sealed, it inhales moist air. This moisture then condenses inside the housing, fogging up the lens (reducing light output) and, more critically, shorting out the LED driver and corroding circuit boards. A simple IP rating on a datasheet doesn't tell this full story.

3. The Dust & Sand Siege: The Grinding Wear-Down

In arid, desert, or industrial areas, dust and sand are more than just a nuisance. They act as a thermal blanket, clogging heat sinks and preventing the LEDs from dissipating heat effectively. This leads to overheating, which is the number one cause of accelerated lumen depreciation (dimming) and premature LED death. Furthermore, fine dust can coat the solar panel, creating a film that can slash energy generation by up to 20-30%, starving the battery and compromising the light's ability to last through the night.

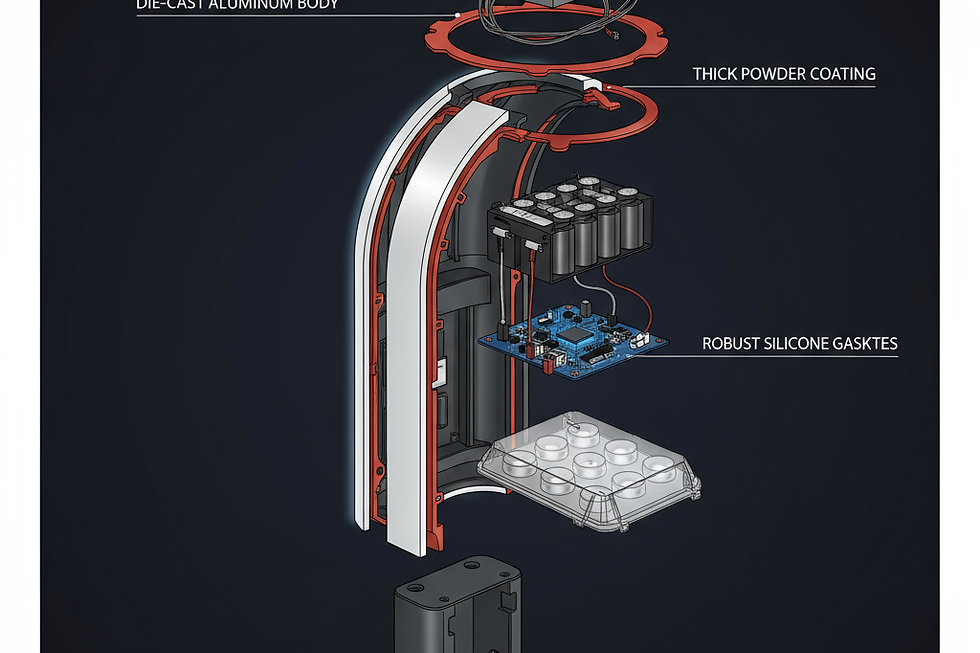

The Armor and Shield: Engineering for Uncompromising Durability

A truly robust solar street light is a system of defenses. It's not about a single feature, but a holistic approach to material science and design engineering that anticipates and neutralizes environmental threats.

1. Material Science is Non-Negotiable: Beyond Basic Aluminum

Not all metals are created equal. While many manufacturers use standard aluminum, elite solutions for harsh environments insist on specific alloys.

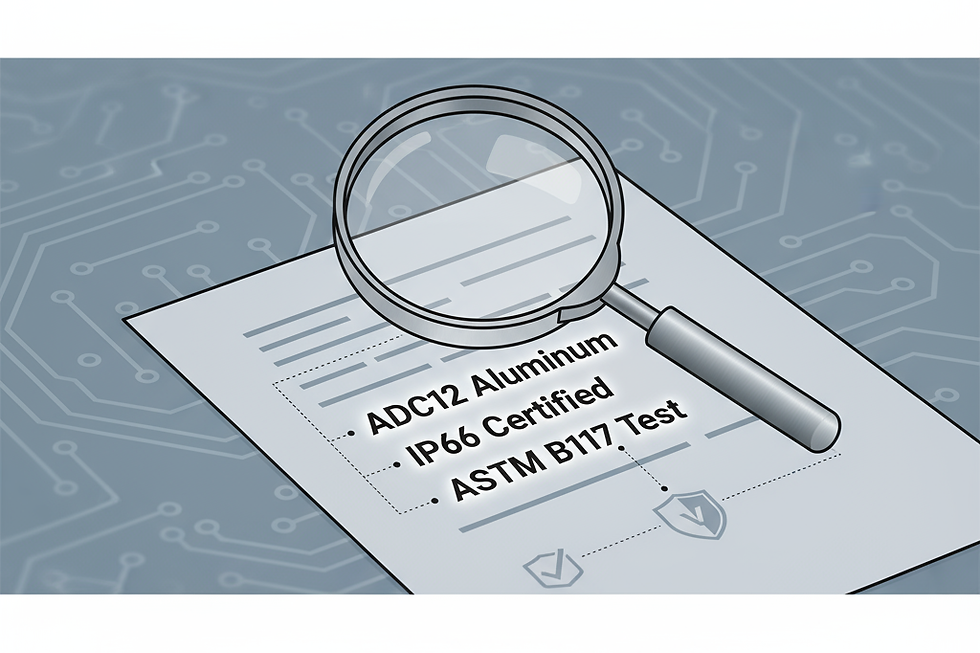

Die-Cast ADC12 Aluminum: This alloy has superior corrosion resistance and strength compared to common 6063 extruded aluminum. The die-casting process also creates a less porous, more uniform housing, which is the first line of defense.

Stainless Steel Fasteners (SUS304/316): Using cheap, galvanized steel screws is a classic mistake. They will be the first point of failure, rusting quickly and staining the fixture. High-grade stainless steel prevents this and avoids creating a galvanic cell with the aluminum housing. From an engineer's perspective, this detail is a clear indicator of quality.

2. A Multi-Layered Defense: The Science of Superior Coatings

An industrial-grade finish is far more than a layer of paint. It's a multi-stage chemical process. For a procurement officer specifying lights for a port or chemical plant, understanding this is key to ensuring a 10+ year service life.

Pre-treatment: The raw aluminum housing must be meticulously cleaned and then undergo a chromate conversion coating (passivation). This step creates a stable, corrosion-resistant surface for the final coat to adhere to.

AkzoNobel Powder Coating: Leading manufacturers use high-performance polyester powder coatings from brands like AkzoNobel. These are electrostatically applied and then cured to form a hard, non-porous finish that is highly resistant to UV degradation, abrasion, and chemical attack. The thickness should be a minimum of 80-100?m.

Proof in Testing: Ask for a Salt Spray Test report (e.g., ASTM B117 for 1000 hours). This document is the ultimate proof that the coating system can withstand a simulated corrosive environment and is a crucial piece of due diligence for any serious project.

3. Sealing the Deal: IP66 is the Starting Point, Not the End Goal

An IP66 rating (dust-tight and protected against powerful jets of water) is the minimum standard. However, superior design goes further.

Silicone Gaskets: Unlike cheaper rubber or foam, silicone gaskets are highly resistant to UV degradation and temperature extremes, ensuring they don't become brittle and fail over time.

Breathable Vents: The most advanced fixtures incorporate a waterproof, breathable membrane (e-PTFE vent). This allows air pressure to equalize between the inside and outside of the fixture without allowing water molecules to enter, effectively stopping the 'breathing' cycle that pulls in humidity.

The Procurement Playbook: How to Specify and Verify a 'Battle-Hardened' Solar Light

As a buyer, you hold the power. You just need to know the right questions to ask and the right evidence to demand. This shifts you from a price-focused buyer to a value-focused investor.

1. Demand the Right Documents: Go Deeper Than the Brochure

Your Request for Quotation (RFQ) should be specific. Don't just ask for a 'corrosion-resistant light'. Demand:

Material Specification Sheet: It must explicitly state the aluminum alloy (e.g., ADC12), fastener material (e.g., SUS304), and coating brand/type.

Third-Party Test Reports: Request the Salt Spray Test report and the IP rating certification. A reputable manufacturer will have these readily available.

Detailed Datasheet: Look for the IK rating (e.g., IK08 or higher), which indicates impact resistance against debris in a storm, a critical factor for project managers in typhoon-prone areas.

2. Scrutinize the Physical Design and Warranty

The design itself reveals a lot. Is the heat sink designed with wide, vertically-oriented fins that allow dust and rain to run off easily, or is it a complex grid that will trap debris? Is the solar panel framed in robust, anodized aluminum? These are tangible signs of purpose-built engineering. Similarly, examine the warranty. A long warranty is meaningless if its fine print excludes 'environmental damage' or corrosion. A confident manufacturer offers a warranty that explicitly covers the finish for a specified period (e.g., 5 years) in corrosive environments.

3. Think Like an NGO Coordinator: Prioritize Low Maintenance

For those deploying lights in remote areas where maintenance is difficult or impossible, features that reduce upkeep are paramount. Look for hydrophobic coatings on the solar panel glass that help rain wash away dust ('self-cleaning' effect) and tool-less entry designs for any component that might eventually need service. These features demonstrate a deep understanding of the entire product lifecycle and the Total Cost of Ownership (TCO), not just the initial sale.

Conclusion: From a Liability to a Long-Term Asset

In extreme environments, a solar street light is not a simple commodity. It is a critical piece of infrastructure that must perform reliably for a decade or more. Opting for a cheaper, under-specified product is not cost-saving; it's simply deferring a much larger cost of replacement and repair.

The shift in mindset is crucial: move from evaluating the initial price to evaluating the long-term resilience. By understanding the specific threats of salt, humidity, and dust, and by demanding proof of the advanced materials, coatings, and engineering designed to combat them, you transform your lighting procurement from a potential liability into a durable, dependable, long-term asset. You are no longer just buying a light; you are investing in peace of mind.

Is Your Project Site an Invisible Battlefield for Your Lighting?

Don't let corrosion and dust sabotage your investment. Choose a solution engineered to win. The team at Novafuture Tech specializes in developing solar lighting systems for the world's most demanding environments.

Contact us for a complimentary project consultation to discuss the specific challenges of your site.

Website: www.nfsolar.net

Email: cocowang@novafuture.net

WhatsApp: +8613013537907

留言