The Invisible Killers: 3 Component Lifespan Traps in China Solar Street Lights That 99% of Designers Overlook

- coco wang

- 2025年10月3日

- 讀畢需時 6 分鐘

The Invisible Killers: 3 Component Lifespan Traps in China Solar Street Lights That 99% of Designers Overlook

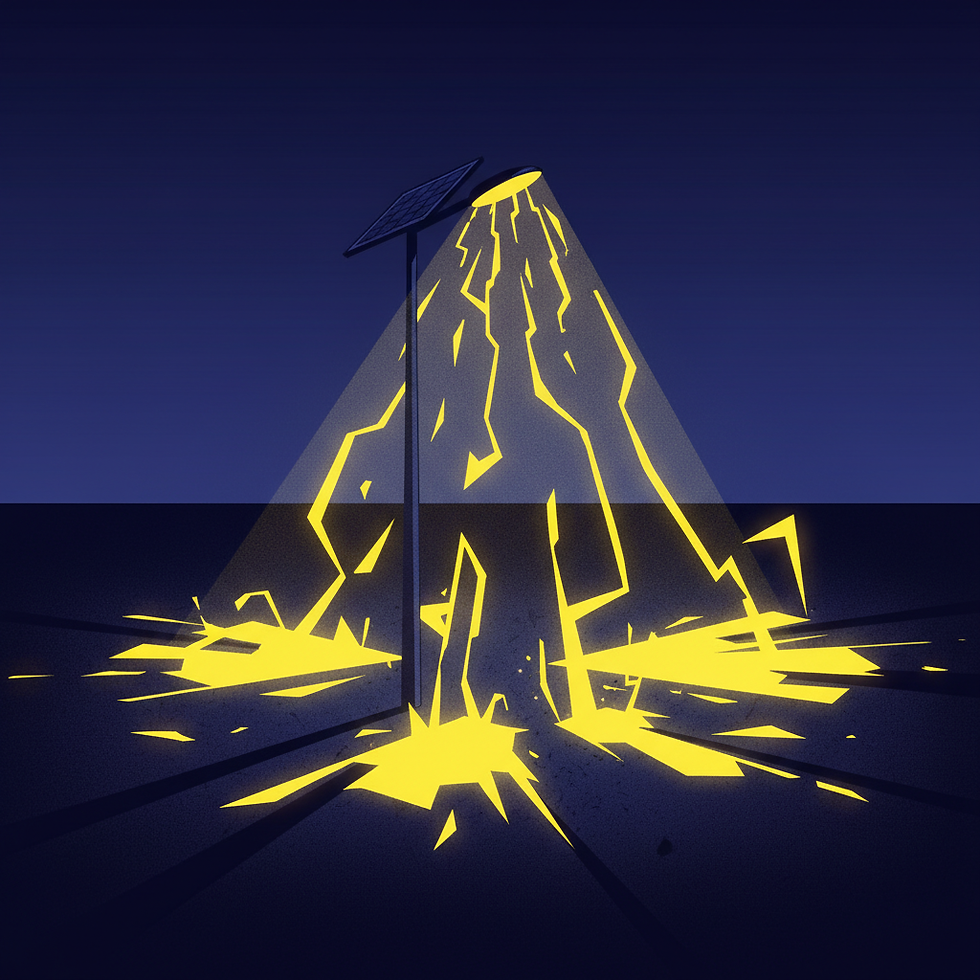

A familiar story plays out in countless projects: a batch of solar street lights, sourced from China with impressive datasheets and a compelling price, are installed. They shine brilliantly for the first six months. The project manager breathes a sigh of relief. Then, the first rainy season hits. One by one, the lights begin to fail. By the one-year mark, a significant portion of the investment is either underperforming or completely dark, leading to angry calls from clients and unplanned, costly maintenance runs.

This scenario isn't a failure of solar technology itself. It's a failure to see beyond the surface specifications. When procuring from a diverse market like China, the most critical battles for a project's long-term success are fought not on the datasheet, but deep within the internal components. These are the invisible killers?the ticking time bombs that separate a reliable, 10-year asset from a 1-year liability.

This article will dissect the three most common and critical component lifespan traps that even experienced professionals can overlook. We will move beyond marketing claims and equip you with the technical insight needed to safeguard your next solar lighting project.

Trap 1: The Battery - More Than Amp-Hours, It's the System's Ticking Clock

The battery is the heart of any solar lighting system, storing the precious energy harvested during the day. However, treating it as a simple commodity based on its rated capacity (Ah) is the first and most dangerous trap. Its true value lies in the quality of its cells, the intelligence of its management system, and the integrity of its construction.

The "Grade-A" Shell Game: The term "Grade-A" is used universally, but its meaning varies wildly. True, top-tier Grade-A LiFePO4 cells from reputable manufacturers are defined by tight tolerances in capacity, internal resistance, and self-discharge rates. The trap is sourcing lights that use Grade-B cells, recycled cells from electric vehicles, or cells that simply failed to meet the Grade-A standard. These cheaper cells may initially meet capacity specs but will suffer from rapid capacity fade and high failure rates, especially under the stress of daily cycling. For an NGO Project Coordinator, this is the difference between a sustainable light source for a village and a failed project that erodes donor confidence.

The Unsung Hero: Why a Smart BMS is Non-Negotiable: The Battery Management System (BMS) is the battery's brain. A quality BMS does more than just prevent catastrophic overcharge or over-discharge. It performs crucial cell balancing, ensuring all cells in the pack age uniformly. It provides temperature compensation, adjusting charge and discharge rates to protect the battery in extreme heat or cold. A cheap, rudimentary BMS lacks these features, leading to imbalanced cells, premature failure of the entire pack, and a significant fire risk. For an Engineer, a spec sheet without detailed BMS parameters is a major red flag.

The Silent Killer: Internal Resistance & Shoddy Wiring: A hidden but lethal factor is high internal resistance, often caused by poor-quality cells, inadequate spot welding between cells, or undersized wiring. High resistance acts like a tax on every watt of power moving in or out of the battery. During charging, it wastes solar energy as heat. During discharging, it causes the voltage to sag, tricking the controller into thinking the battery is empty when it isn't. This heat build-up silently degrades the cells, drastically shortening the battery's operational life long before its rated cycle count is reached.

Trap 2: The Light Engine - When "Bright" Today Means Dark Tomorrow

The LED light engine is the face of the project, delivering the illumination that defines its success. But the initial brightness can be a deceptive lure, masking underlying issues that will prematurely plunge the site into darkness.

LED Chip Roulette: Beyond the Brand Name: Many suppliers will proudly state they use chips from reputable brands like Bridgelux or Cree. However, these manufacturers produce various quality levels, or "bins," of chips. The trap is using lower-bin chips that, while authentic, have lower efficiency and poorer thermal and color stability. This results in two major problems for a Government Procurement Officer: rapid lumen depreciation (the light gets dimmer much faster than the L70 rating suggests) and color shifting (a crisp white light degrades into a sickly blue or yellow), failing public lighting standards and requiring premature replacement.

The Driver's Deadly Sin: Inefficiency as a Heat Bomb: The LED driver converts the battery's DC power to the specific voltage and current the LEDs need. An inefficient driver is a double penalty. First, it wastes precious battery energy?a 10% efficiency loss is like throwing away an hour of sunlight each day. Second, and more critically, that wasted energy is converted directly into heat. This heat is generated right next to the LEDs and other sensitive electronics. This "heat bomb" effect accelerates LED lumen decay and is the number one cause of premature failure in electronic components like capacitors, fundamentally compromising the entire system's reliability.

Trap 3: The Controller - The "Brain" with a Fatal Flaw

The solar charge controller is the system's central nervous system, managing the flow of energy from the solar panel to the battery and the light. A failure here renders the entire unit useless, no matter how good the other components are.

The MPPT vs. PWM Deception: Maximum Power Point Tracking (MPPT) controllers are superior to Pulse Width Modulation (PWM) controllers, often harvesting up to 30% more energy. The trap is the "fake MPPT"?a cheaper PWM controller programmed to mimic some MPPT behavior, or a true MPPT controller built with substandard components that either fail quickly or perform inefficiently. For a Distributor, selling a product based on a deceptive MPPT claim can destroy their market reputation when the lights underperform in winter months.

"Capacitor Plague" and Component Anemia: The lifespan of any electronic circuit is determined by its weakest link, which is often the capacitors. Low-cost controllers use standard electrolytic capacitors with a low temperature rating (e.g., 85�C) and short operational life. When placed inside a sealed, sun-baked metal housing, these capacitors are quickly cooked, leading to controller failure. A premium controller uses high-temperature (105�C or higher) rated, long-life capacitors and robust MOSFETs that can handle the electrical stress without overheating, ensuring the brain operates flawlessly for years.

The False Promise of IP Ratings: The Threat of Internal Corrosion: An IP65 or IP66 rating is essential, but it only tests against the ingress of dust and water from the . It doesn't account for temperature cycles causing air inside the housing to expand and contract, drawing in moist air. This moisture can then condense directly onto the controller's circuit board. The trap is relying solely on the housing's IP rating. The real solution is a controller board protected by a conformal coating or, for maximum reliability, one that is fully potted in waterproof, heat-dissipating epoxy. This prevents corrosion and short circuits even if moisture gets inside, a critical feature for any long-term deployment, especially in coastal or tropical regions.

Your Strategic Defense: A Procurement Guide for the Savvy Buyer

To navigate these traps, you must shift your procurement strategy from accepting specifications to actively interrogating them. A professional supplier will welcome this scrutiny.

Demand Component-Level Transparency: Don't just accept "Grade-A LiFePO4." Ask for the cell manufacturer, model number, and production date codes. Request the brand and model of the LED chips, driver IC, and key controller components like MOSFETs and capacitors.

Scrutinize the Thermal Design: A render of the heat sink is not enough. Ask for the calculated thermal resistance or at least a clear explanation of how heat is moved from the LED chips and driver components to the outside of the luminaire. A well-engineered thermal path is a clear sign of a quality product.

Go Beyond the Warranty Document: A 3- or 5-year warranty is meaningless if the company won't be there to honor it. Investigate the supplier's history and track record. More importantly, ask for specific performance warranties, such as a guarantee that the battery capacity will remain above 80% after a certain number of cycles, or that lumen depreciation will not exceed 20% within 5 years.

Conclusion: From Price-Per-Unit to Value-Over-Lifetime

The recurring failures in solar street lighting projects are rarely a surprise; they are the predictable result of hidden compromises made deep inside the product. The initial price tag on a datasheet does not reflect the true cost of a system plagued by low-grade batteries, inefficient light engines, and vulnerable controllers.

To truly succeed, we must evolve our thinking from a simple procurement mindset to a strategic investment mindset. This means looking past the promises on the surface and developing the expertise to identify the quality?or lack thereof?within. By understanding these three invisible killers, you are no longer just a buyer; you are an informed investor, capable of securing a reliable, high-performance lighting system that delivers value year after year.

Don't Let Hidden Flaws Derail Your Project. Let's Build Reliability, Together.

Navigating the complexities of component quality is challenging. If you're ready to partner with a team that prioritizes transparent, engineering-first solutions, we're here to help.

Contact the nfsolar team for expert guidance on your next project.

Website: www.nfsolar.net

Email: cocowang@novafuture.net

WhatsApp: +8613013537907

留言