Is Your Solar Street Light Pole a Ticking Time Bomb? The 2025 Guide to Failure-Proofing Your Project

- coco wang

- 2025年9月30日

- 讀畢需時 5 分鐘

A hurricane is brewing, and as a project manager, you?re not just watching the weather report?you?re picturing your assets on the ground. Will those newly installed solar street lights, the ones that represent a significant capital investment, still be standing tomorrow? This isn't just a question of durability; it's a question of project viability, public safety, and your professional reputation.

For too long, the pole has been the forgotten component of the solar lighting system, treated as a mere commodity. This is a strategic error that costs municipalities, contractors, and developers millions in replacements and liability. The pole isn't just a mount; it's the foundational backbone of the entire system. Its failure means total system failure.

This guide moves beyond simplistic specifications. We will dissect the critical elements of structural design and material science that separate a resilient, long-lasting solar street light pole from a catastrophic failure waiting to happen. It's time to stop buying a piece of metal and start investing in long-term structural integrity.

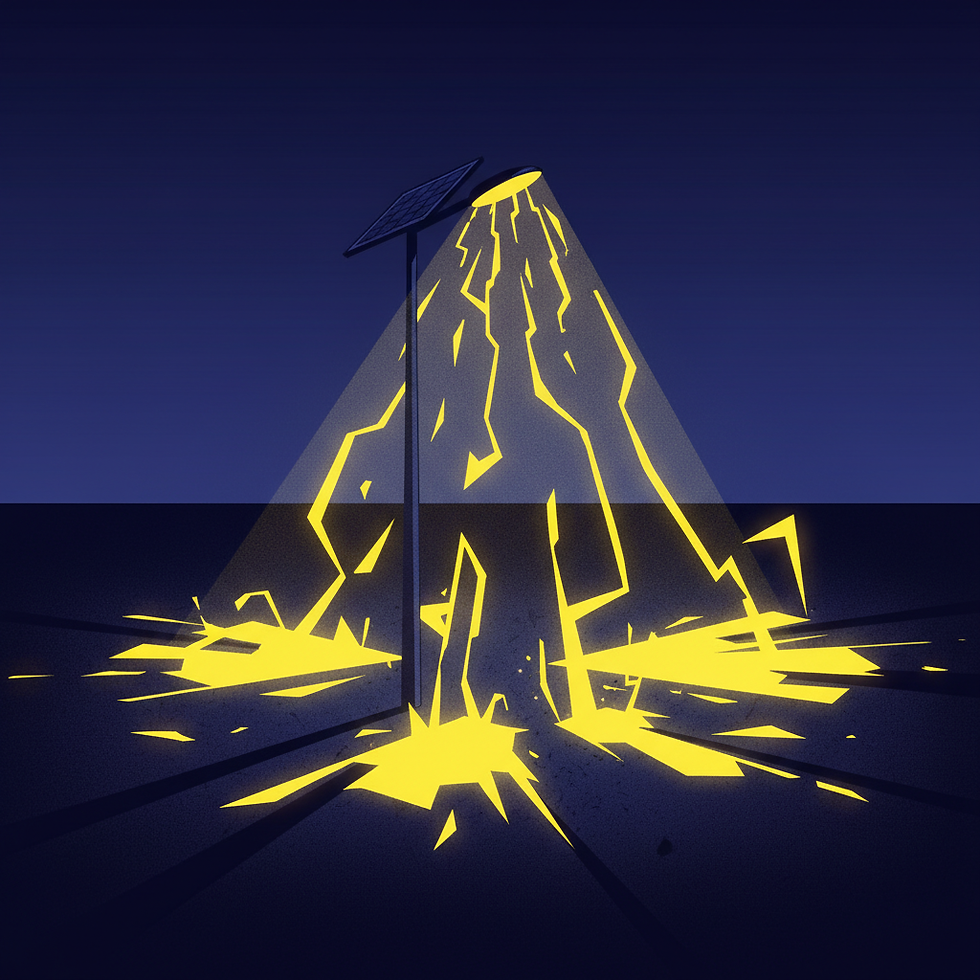

The Invisible Force: Why Wind Load is a Project-Killer, Not Just a Number

Underestimating the relentless force of wind is the single most common reason for the structural failure of solar street light poles. It?s not just about the pole itself; it?s about how the entire assembly?pole, panel, and luminaire?interacts with these forces.

A Plain English Guide to Wind Load Standards (ASCE 7, EN 40)For an engineer, these codes are the bible. But for a project manager or procurement officer, they can be opaque. In essence, these standards help calculate the 'Effective Projected Area' (EPA) of your entire assembly. Think of it as the size of the 'sail' you're presenting to the wind. A larger solar panel and luminaire create a bigger sail, dramatically increasing the stress at the base of the pole. Insist that your manufacturer provides calculations based on these standards for your specific project location's maximum recorded wind speed, not just a generic rating.

The 'Sail Effect' Penalty: How Oversized Components Doom Your PoleThe drive for more power often leads to specifying oversized solar panels. While this seems logical for energy autonomy, it can be a fatal structural decision. For example, increasing a solar panel's size by 30% doesn't just increase the wind load by 30%; it can amplify the torque and vibrational stress on the pole exponentially, leading to fatigue and failure over time, even in non-hurricane conditions. A well-designed system balances energy needs with structural stability.

Beyond the Pole: The Unsung Hero of Your FoundationA pole is only as strong as its foundation. An undersized or improperly installed concrete base is a frequent point of failure. The soil condition of your project site is a critical variable. Sandy, loose soil requires a much deeper and wider foundation than compact, stable ground. A geotechnical report isn't a 'nice-to-have'; it's an essential piece of data for ensuring your multi-thousand-dollar investment doesn't simply tip over.

The Slow Killer: Winning the War Against Corrosion Before It Starts

If wind is the sudden, violent threat, corrosion is the silent assassin that undermines your pole's strength over years. For coastal projects or industrial zones with airborne pollutants, selecting the right protective coating is as crucial as calculating wind load.

The Galvanization Gauntlet: Not All Zinc Coatings Are EqualHot-dip galvanizing (HDG) is the industry standard, creating a metallurgical bond between zinc and steel. But the of this layer, measured in microns, is what matters. A standard G90 coating might be sufficient for a dry, inland climate, but a coastal installation buffeted by salt spray demands a much thicker layer. Ask your supplier for the specific galvanization standard they adhere to (e.g., ASTM A123) and the certified coating thickness. This single data point can predict a pole's lifespan.

Choosing Your Armor: Powder Coating and Duplex SystemsFor the harshest environments, a 'duplex system'?a combination of hot-dip galvanizing followed by a durable powder coat?offers the ultimate protection. The galvanization provides the primary anti-corrosion layer, while the powder coat acts as a tough, aesthetic barrier against abrasion, UV rays, and chemical exposure. This is the specification of choice for government projects where a 25+ year design life is a non-negotiable requirement.

The Hidden Weakness: Why Fasteners and Welds Are Ticking Time BombsA chain is only as strong as its weakest link. It's common to see a perfectly galvanized pole installed with cheap, non-galvanized bolts. These fasteners will rust within months, staining the pole and creating a point of structural weakness. Likewise, if welding is performed galvanization, the protective zinc layer is burned away, creating an immediate entry point for corrosion. Insist on post-weld galvanizing and the use of properly rated, hot-dip galvanized fasteners.

The Future is Light & Strong: A Material Scientist's View of Modern Poles

The traditional galvanized steel pole is a workhorse, but advancements in material science are providing new options that offer compelling advantages in logistics, installation, and long-term performance.

The Great Debate: High-Strength Aluminum vs. Traditional SteelMarine-grade aluminum alloys (like 6061-T6) offer excellent corrosion resistance without needing any coating, making them ideal for coastal areas. The primary advantage, however, is weight. An aluminum pole can be up to 60% lighter than a steel pole of equivalent strength. For a project manager, this translates directly into reduced shipping costs and faster, easier installation, often without the need for a crane. This can significantly lower the Total Cost of Ownership (TCO), even if the initial material cost is higher.

The Rise of Composites: Are Fiberglass Poles Ready for Prime Time?Fiberglass Reinforced Polymer (FRP) poles are the next frontier. They are lightweight, completely immune to corrosion and electrical conductivity, and can be engineered for immense strength. While currently a premium option, their 'install-and-forget' nature is incredibly appealing for Facility Managers concerned with long-term maintenance. They are particularly valuable in areas with high electrical storm activity or where non-conductivity is a safety requirement.

A Critical Note on Seismic DesignFor projects in earthquake-prone regions, the pole's ability to withstand seismic forces is paramount. This involves not just material strength but also the design of the base connection, which must allow for a degree of flexion without catastrophic failure. Ensure your manufacturer can provide data on the pole's seismic performance and compliance with local building codes for these specific environmental challenges.

Conclusion: From Commodity to Cornerstone?Rethinking the Pole

The conversation around solar street lights must evolve. We must move past a myopic focus on the luminaire and battery and embrace a systemic view where the structural pole is given the respect it deserves. A robust, correctly specified pole is not an expense; it's the insurance policy on your entire investment.

To ensure your project's success and longevity, you must upgrade your procurement framework:

From a generic spec to a site-specific solution: Demand wind load calculations and foundation recommendations tailored to your project's geography.

From a visual check to a materials deep-dive: Scrutinize the specifics of anti-corrosion treatments and material grades.

From upfront cost to lifecycle value: Analyze how lighter, more durable materials can reduce installation and maintenance costs over the project's lifetime.

By asking these tougher, more intelligent questions, you transform yourself from a buyer into a strategic partner, ensuring that your solar lighting project not only shines brightly but also stands strong for decades to come.

Is Your Project Built to Last?

Don't let structural oversight compromise your investment. The difference between a resilient project and a costly failure lies in the details. Connect with the expert team at Novafuture Tech for a professional consultation on your specific project requirements.

Website: www.nfsolar.net

Email: cocowang@novafuture.net

WhatsApp: +8613013537907

留言