Beyond the Spec Sheet: 3 Fatal Thermal Traps 90% of Engineers Overlook in Integrated Solar Street Lights

- coco wang

- 2025年10月28日

- 讀畢需時 5 分鐘

Beyond the Spec Sheet: 3 Fatal Thermal Traps 90% of Engineers Overlook in Integrated Solar Street Lights

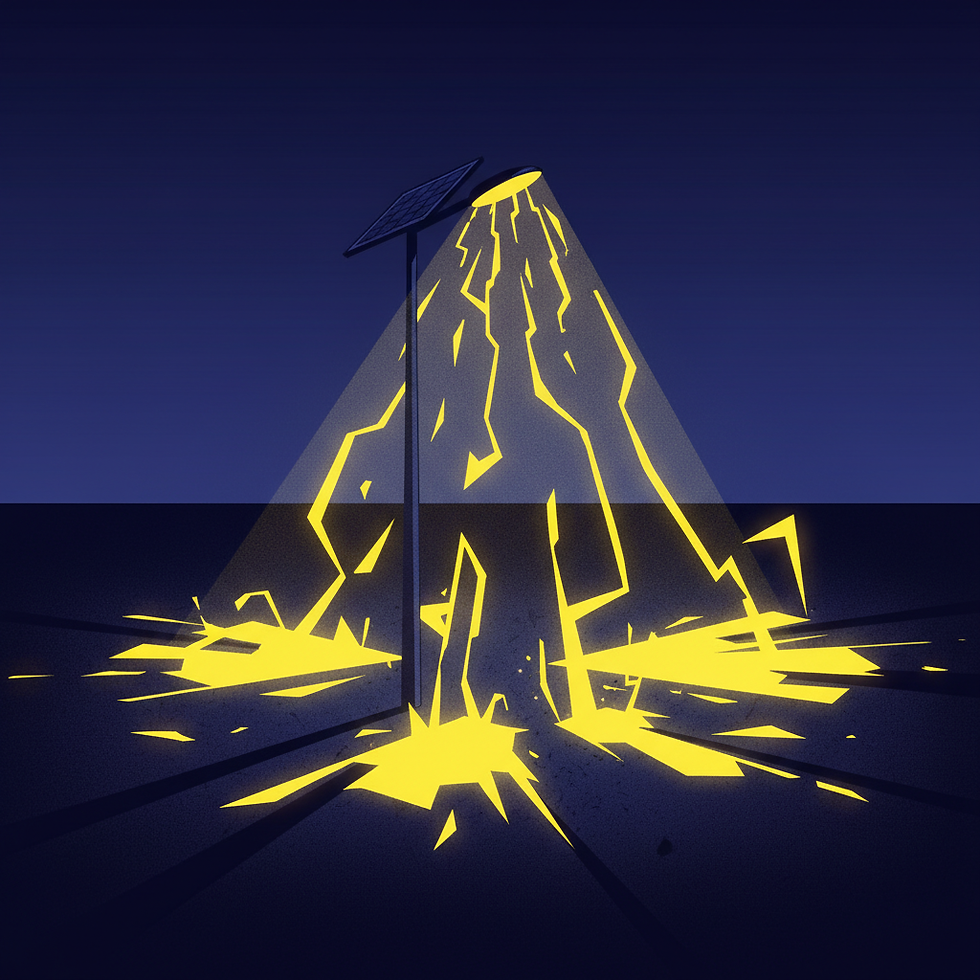

The allure of the integrated solar street light is undeniable. Its sleek, all-in-one design promises simplicity, rapid installation, and a clean aesthetic. For project managers and engineers, it seems like the perfect modern solution. However, this compact elegance conceals a complex and ruthless enemy: heat. A failure to manage this invisible threat is the single largest contributor to premature failures, budget overruns, and damaged professional reputations.

Too many procurement decisions are driven by impressive numbers on a datasheet?high lumen output, large battery capacity, competitive pricing. But the real determinant of a product's long-term value and reliability isn't on that sheet. It?s in the sophisticated thermal engineering required to prevent the unit from slowly cooking itself to death. This article, written from the perspective of a 15-year veteran in solar lighting architecture, will expose three fatal thermal traps that are consistently overlooked and provide a technical framework for identifying truly robust, project-ready solutions.

Trap 1: The "Component Coffin" ? Mismanaging Internal Heat Congestion

The very feature that makes integrated lights attractive?packing the LED module, battery, and controller into one housing?creates a thermal battleground. When not expertly managed, the enclosure becomes a coffin where heat-generating components suffocate each other, leading to a cascade of failures.

1. The Battery's Silent Scream

Heat is the arch-nemesis of battery longevity. In a poorly designed integrated unit, the heat generated by the high-power LED module (which can easily reach 60-80�C) radiates directly onto the battery pack. For LiFePO4 chemistry, sustained exposure to temperatures above 45�C causes irreversible capacity degradation and drastically shortens its cycle life. An engineer might specify a battery for a 5-year lifespan, but if it?s constantly being cooked, it may fail in under two years, torpedoing the project's Total Cost of Ownership (TCO).

2. The Controller's Choke Point

The MPPT controller is the light's brain, but it's also a heat source. Squeezed between a hot LED panel and a warm battery, its own operating temperature rises. This leads to two problems: first, the efficiency of its electronic components drops, meaning more energy is wasted as heat; second, critical components like capacitors age exponentially faster at higher temperatures. This can lead to erratic behavior?like flickering lights or charging failures?long before the unit's warranty expires.

3. The Myth of the Shared Heatsink

A common design shortcut is to use the light's entire aluminum body as a universal heatsink. This is a fundamentally flawed concept if there is no internal thermal isolation. Instead of efficiently drawing heat away from the primary source (the LEDs) and expelling it, the body becomes an oven. It simply averages out the temperature, ensuring all components?including the heat-sensitive battery and controller?are subjected to elevated temperatures. A superior design isolates the heat sources and creates dedicated thermal pathways for each.

Trap 2: The "Performance Mirage" ? Ignoring High and Low Temperature Extremes

A spec sheet that promises flawless performance at a comfortable 25�C (77�F) is creating a performance mirage. The real world operates in punishing extremes, and a design that isn't explicitly engineered for them will fail. This is where most spec-sheet-driven decisions prove disastrously wrong.

1. The High-Temp Cascade Failure

Consider a project in the Middle East or Sub-Saharan Africa. The ambient air temperature can hit 45�C. Add intense solar radiation (solar gain) on the metal housing, and the unit's internal temperature can soar past 70�C before the light even turns on. Once the high-power LEDs activate, this creates a perfect storm for thermal runaway. The immediate result is a sharp drop in LED efficiency and accelerated lumen depreciation. The long-term result is catastrophic: the battery's BMS may trigger a high-temperature safety shutdown, plunging the area into darkness and creating a massive reliability issue for a municipal client or NGO partner.

2. The -40�C Challenge: The Cold's Crippling Effect

In frigid climates, the thermal challenge is inverted but no less deadly. Standard lithium-ion batteries suffer permanent damage (a phenomenon called lithium plating) if charged at temperatures below 0�C (32�F). A basic controller will simply cut off charging, effectively starving the system of energy during the shortest days of the year. A truly robust cold-climate design requires an intelligent Battery Management System (BMS) with two critical features: a low-temperature charging cut-off a regulated internal heating element. This heater uses a small amount of battery energy to warm the cells to a safe charging temperature, ensuring the system can reliably harvest solar energy even on the coldest days.

Trap 3: The "Paper Tiger" ? Relying on Inadequate Validation & Materials

An elegant design concept is nothing more than a "paper tiger" if it isn't backed by high-quality materials and validated by rigorous, real-world testing. Engineers and project managers must learn to look beyond the marketing claims and demand objective proof of thermal performance.

1. Beyond the Heatsink Fins: The Material Question

The presence of cooling fins is not a guarantee of performance. The key is the material and the interface. Is the housing made from high-purity ADC12 die-cast aluminum, known for its excellent thermal conductivity, or a cheaper, less effective alloy? Even more critical is the Thermal Interface Material (TIM)?the paste or pad between the LED circuit board and the heatsink. Using a low-quality TIM creates a thermal bottleneck that renders the entire heatsink design ineffective. It's a tiny detail that can make the difference between a 10-year product and a 2-year failure.

2. The Missing Test Report: Demanding Proof of Performance

A spec sheet is a claim; a third-party test report is evidence. For any serious project, demand to see the thermal testing data. This includes thermal simulation reports that model heat flow, but more importantly, physical test reports like an ISTMT (In-Situ Temperature Measurement Test) or a temperature rise test. These reports will show the actual steady-state operating temperature of the LED junction (Tj), the controller, and the battery core inside the sealed unit. If a manufacturer cannot provide this data, it's a major red flag.

3. The Ventilation Fallacy: When Vents Become a Liability

Some designs incorporate vents to promote "air cooling." While this may look good in a lab, it's often a disastrous feature in the field. In dusty, coastal, or industrial environments, these vents become gateways for dust, salt fog, and moisture. Over time, this ingress compromises the IP rating, causes internal corrosion, and leads to electrical short circuits. A truly robust, maintenance-free design almost always relies on a fully sealed (IP66 or higher) enclosure that uses a massive passive cooling surface area, not flimsy vents, to manage heat.

Conclusion: From "Wattage Worship" to a Thermal-First Mindset

The procurement of integrated solar street lights must evolve. We must move beyond a superficial comparison of watts and lumens and adopt a rigorous, reliability-focused evaluation process centered on thermal management.

The three traps?internal heat congestion, a failure to design for environmental extremes, and reliance on unvalidated claims?are the primary drivers of the costly, premature failures that plague so many solar lighting projects. By learning to identify these pitfalls, you shift from being a buyer to being a strategic partner in your project's success.

A truly exceptional integrated solar street light is not just a collection of components in a box; it is a holistically engineered thermal system. Choosing wisely means demanding proof of this engineering, ensuring your investment is built for the harshest realities of the field, not just the pristine conditions of a spec sheet.

Ready to Move Beyond the Spec Sheet?

Don't let hidden thermal flaws derail your next project. Secure long-term reliability with expertly engineered solutions designed for the real world.

For in-depth Project Consultation or Product Inquiries, connect with our specialists.

Website: www.nfsolar.net

Email: cocowang@novafuture.net

WhatsApp: +8613013537907

留言