Beyond the Spec Sheet: 3 Fatal Thermal Traps in Solar Street Lights That Can Derail Your Project

- coco wang

- 2025年9月20日

- 讀畢需時 7 分鐘

Beyond the Spec Sheet: 3 Fatal Thermal Traps in Solar Street Lights That Can Derail Your Project

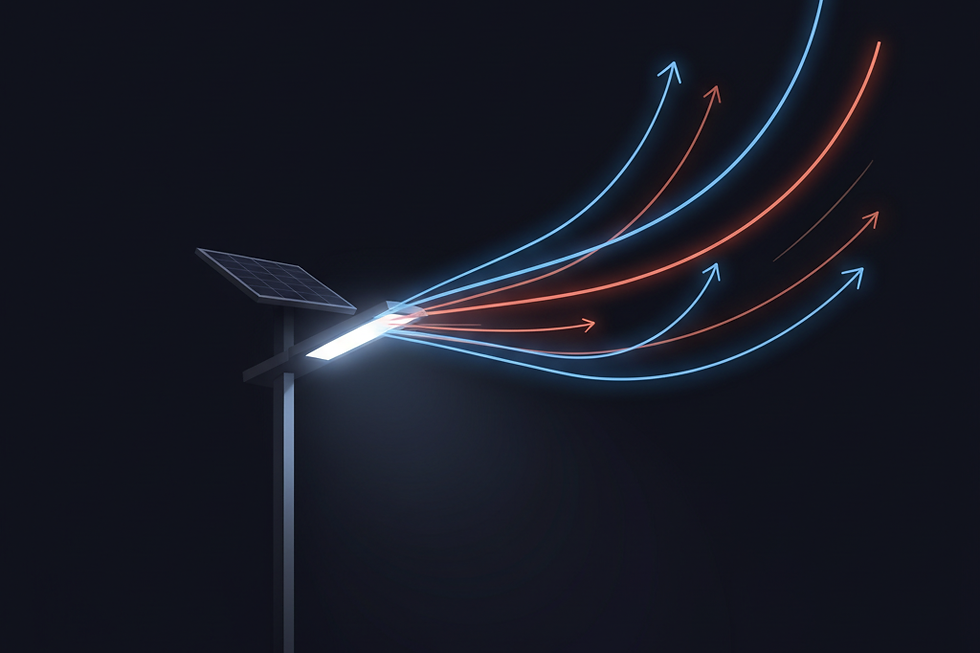

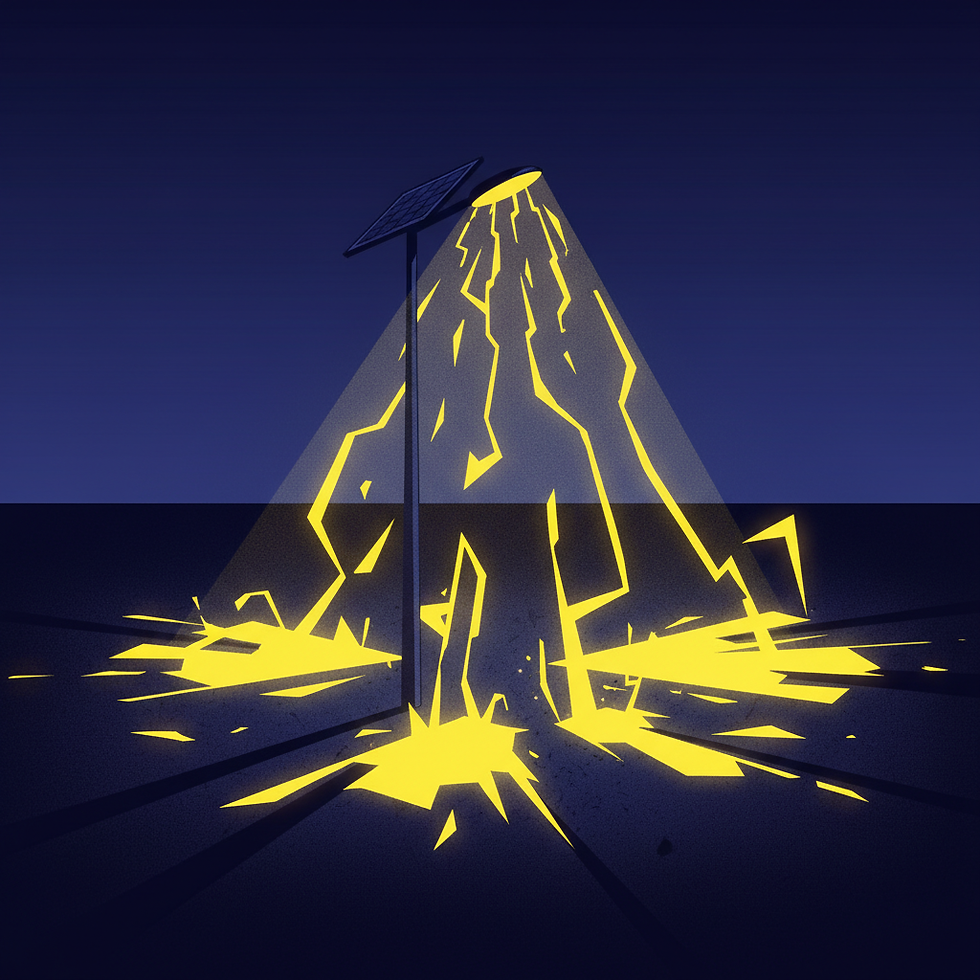

A familiar story unfolds on a project site: a row of solar street lights, installed less than two years ago, begins to fail. One light is dim, another flickers, and a third is completely dead. The immediate suspects are always the battery or the solar panel. But more often than not, the true culprit is a silent assassin: heat. In the world of solar LED lighting, thermal management isn't just a feature; it's the foundation of reliability and the single biggest factor determining whether your investment shines for a decade or fails in a season.

Focusing solely on lumens, watts, or battery capacity while ignoring the system's ability to stay cool is a strategic error. It leads to premature failures, costly maintenance calls, and a damaged professional reputation. This article will move beyond the surface-level specifications to uncover the three most common and fatal thermal management traps that even experienced engineers can overlook. We will build a framework for you to critically assess the thermal design of any solar street light, ensuring your project's long-term success.

The Core Enemy: Why Heat is the #1 Killer of LED Systems

Before we dive into the traps, we must establish a clear understanding of the enemy. Heat is not a minor inconvenience; it is an aggressive force that systematically dismantles every critical component in a lighting fixture, directly answering the question of why some solar lights fail so quickly.

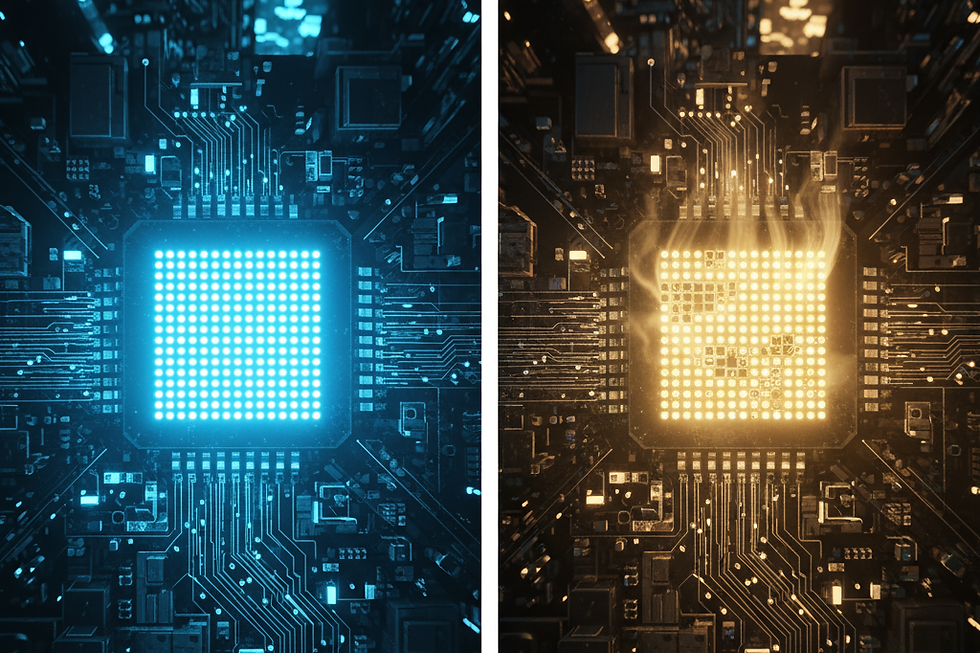

1. The Science of Droop and Decay: A Vicious Cycle

An LED is a semiconductor, and its performance is intrinsically tied to its operating temperature. As the internal temperature (junction temperature) of the LED chip rises, two negative things happen. First, its efficiency "droops," meaning it converts more electricity into heat and less into light. Second, this excess heat accelerates the permanent degradation of the LED materials. Think of it like running a car engine constantly in the red zone?it might work for a while, but catastrophic failure is inevitable. A common rule of thumb in electronics is that for every 10�C increase in operating temperature, the component's lifespan is cut in half. This is why a light's L70 rating (the time it takes to degrade to 70% of its initial brightness) is meaningless without knowing the temperature at which it was tested.

2. The Chain Reaction of Failure: Collateral Damage

Heat doesn't just attack the LED chip in isolation. It wages a war on the entire system. The driver, which is the electronic brain of the light, contains temperature-sensitive components like electrolytic capacitors. When constantly baked at high temperatures, their lifespan plummets, leading to flickering or total failure. The plastic or polycarbonate lenses can yellow and become brittle under prolonged heat exposure, ruining the light distribution. In an integrated all-in-one light, heat from the LED can even radiate to the battery compartment, accelerating the battery's chemical degradation and shortening its cycle life?a critical limitation of poorly designed solar street lights.

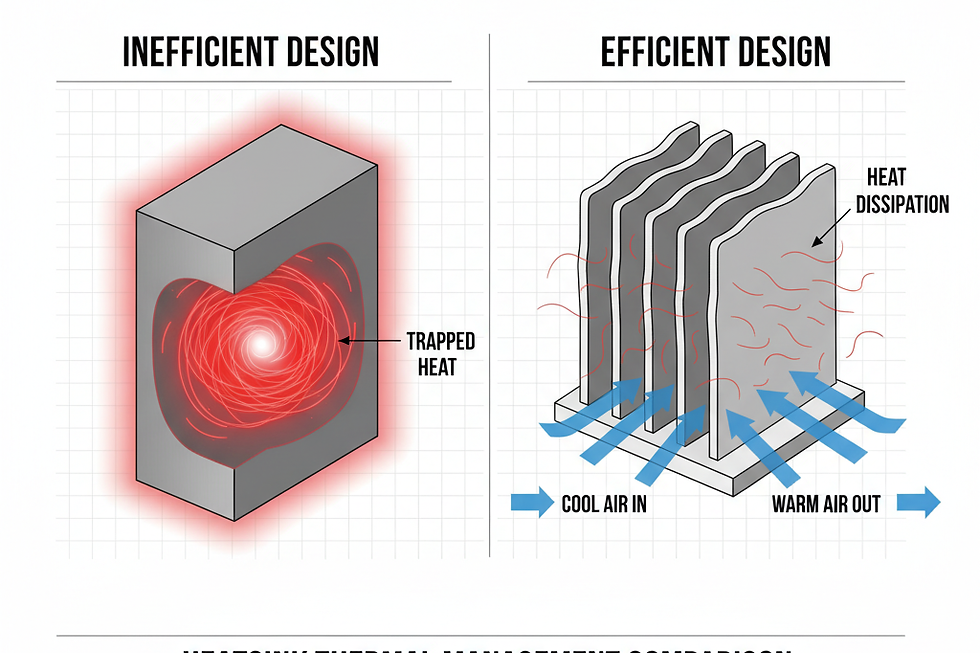

Trap #1: The "Bigger is Better" Heatsink Fallacy

The most common misconception is that a large, heavy piece of aluminum automatically equals good thermal management. This leads procurement managers to judge a light's quality by its weight, a dangerously flawed metric.

1. Surface Area vs. Airflow: The Misunderstood Partnership

A heatsink's job is not just to absorb heat, but to transfer it to the surrounding air. This requires two things: maximum surface area and effective airflow. A massive, solid block of metal has poor surface area-to-volume ratio. A well-engineered heatsink uses intricately designed fins to dramatically increase the surface area that comes into contact with the air. Furthermore, the fins must be designed to promote natural convection, allowing cool air to flow in from the bottom and hot air to exhaust from the top. A heavy, poorly designed heatsink is like having a giant car radiator with no grille for air to pass through?it's just dead weight.

2. The Hidden Cost of Poor Material Choices

Not all aluminum is created equal. Many low-cost lights use die-cast aluminum (like ADC12), which is easy to mold into complex shapes but has mediocre thermal conductivity (around 96 W/mK). High-performance fixtures often use extruded aluminum (like 6063), which has more than double the thermal conductivity (around 201 W/mK). This means heat travels away from the LED chip far more efficiently. From a project manager's perspective, a light made from superior materials may have a slightly higher upfront cost but prevents the far greater expense of future replacements.

3. The Integrated Design Dilemma

For all-in-one solar lights, thermal design is even more critical. The LED, controller, and battery are all generating heat within a single sealed enclosure. A fatal design flaw is to have these components packed tightly together without any thermal isolation. A superior design will feature separate, ventilated compartments or internal heat shields to prevent the LED's waste heat (which can reach 60-80�C) from cooking the battery (which should ideally operate below 45�C). When evaluating an integrated light, always ask the manufacturer how they prevent thermal cross-contamination between components.

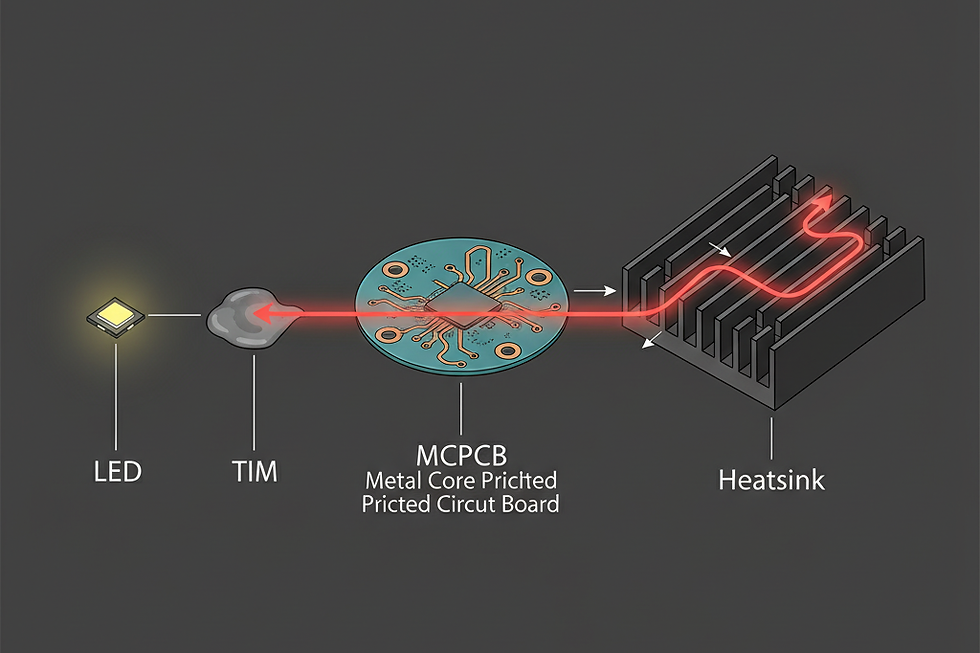

Trap #2: Ignoring the "Thermal Pathway" From Chip to Air

Even with the best heatsink, heat must first travel from its source?the tiny LED chip?to the outside world. This journey, known as the thermal pathway, is only as strong as its weakest link. A single bottleneck can render the entire cooling system useless.

1. The Overlooked Role of Thermal Interface Material (TIM)

Between the LED's circuit board (PCB) and the main heatsink, there is a micro-thin layer of thermally conductive paste or a pad. This TIM is designed to fill microscopic air gaps between the two surfaces, as air is a terrible conductor of heat. Using a cheap, low-quality TIM or applying it incorrectly is a common cost-cutting measure that creates a massive thermal barrier. It's the equivalent of building a six-lane superhighway that funnels into a single dirt track. The heat gets stuck, the LED temperature skyrockets, and the light fails, even if the external heatsink feels cool to the touch.

2. PCB Material Matters: Aluminum vs. FR-4

The circuit board the LEDs are mounted on is another critical link. For any high-power lighting application, a Metal Core PCB (MCPCB) is non-negotiable. These boards have a base layer of aluminum that spreads heat laterally and transfers it efficiently to the main heatsink. Lower-quality products might use standard FR-4 (fiberglass) boards, which are excellent electrical insulators but also terrible thermal conductors. Using FR-4 for anything more than very low-power LEDs is a recipe for rapid failure.

Trap #3: The "Set and Forget" Operational Temperature Blind Spot

Engineers and project managers often rely on datasheet specifications without considering the harsh realities of the installation environment. This is perhaps the most dangerous trap, as it creates a false sense of security.

1. Lab Data vs. Desert Heat: The Datasheet Fantasy

An LED's L70 lifetime of "50,000 hours" is almost always rated at an ambient temperature of 25�C (77�F). However, a solar street light in the Middle East, Africa, or even a hot US state like Arizona can experience ambient temperatures exceeding 45�C (113�F). When you add the heat generated by the sun on the fixture's dark-colored body, the internal operating temperature can be far higher than the lab-tested conditions. This real-world thermal stress can slash the actual lifespan to a fraction of what's printed on the datasheet. A responsible manufacturer will provide L70 data at various, higher ambient temperatures.

2. The Power-Temperature Connection

There's a direct link between a light's power consumption (Watts) and its heat output. This is where system efficiency becomes a thermal management tool. Consider two lights that produce the same 8,000 lumens:

Light A (Low Efficacy): A 100W light at 80 lm/W. It converts a huge amount of energy into waste heat.

Light B (High Efficacy): A 50W light at 160 lm/W. It produces the same amount of light but generates significantly less heat.

Light B is inherently easier to cool, putting less stress on every component and dramatically increasing its real-world reliability and lifespan. Chasing high wattage instead of high luminous efficacy (lm/W) is a common mistake that directly leads to thermal problems.

Conclusion: From Spec-Based Buying to Engineering-Aware Procurement

Moving past the common traps of thermal management requires a shift in perspective. It's about understanding that a solar street light is not a simple commodity but a complex engineered system where heat is the primary adversary. The true measure of a product's quality lies not in its weight or its wattage, but in the intelligence of its design to combat this relentless enemy.

By avoiding these three fatal traps, you transform your procurement process:

You'll look past the heatsink's size and inquire about its fin design, material conductivity, and airflow dynamics.

You'll ask about the unseen details like the quality of the thermal interface material and the type of PCB used.

You'll challenge the datasheet by considering your project's specific climate and prioritizing high-efficacy systems that generate less heat from the start.

Making these questions part of your vetting process is the single most effective way to protect your investment, minimize long-term operational costs, and ensure your project delivers safe, reliable lighting for years to come.

Tired of Worrying About Hidden Flaws in Your Solar Lighting?

Ensure your next project is built on a foundation of reliability. Reach out to the experts at nfsolar for a professional consultation. We help you ask the right questions and choose solutions engineered to last in the real world.

Contact us for Project Consultation or Product Inquiries:

Website: www.nfsolar.net

Email: cocowang@novafuture.net

WhatsApp: +8613013537907

留言