Don't Let Your Solar Lights Cook: The Hidden Science of Thermal Management

- coco wang

- 2025年10月28日

- 讀畢需時 5 分鐘

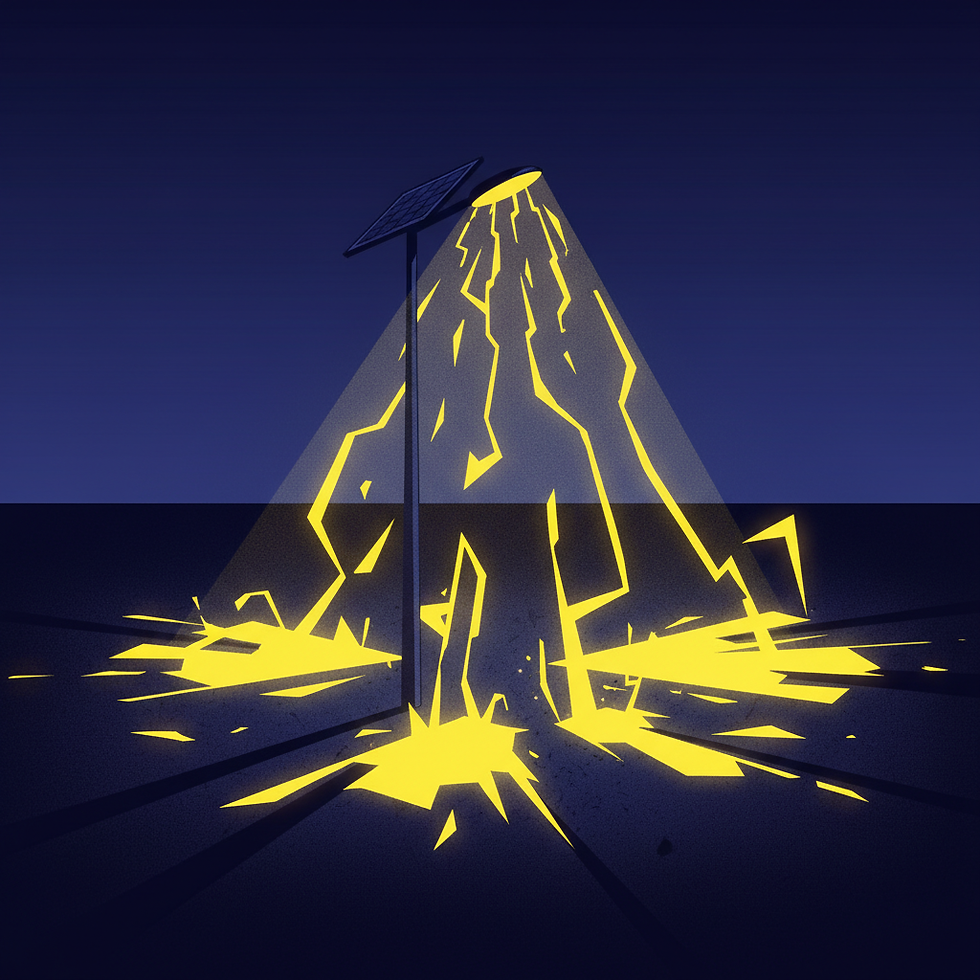

In the world of solar street lighting, the integrated, all-in-one design is a marvel of engineering efficiency. But this compact form factor creates an intense internal battle against an invisible enemy: heat. For project managers, engineers, and procurement officers, overlooking this challenge is the single most common path to premature failure, budget overruns, and compromised public safety, especially in regions with extreme climates.

Think of an integrated solar light as a sealed pressure cooker. Inside, the LED module, the lithium battery, and the charge controller are all generating and absorbing heat in a confined space. Without a sophisticated strategy to manage this thermal load, you're not investing in a lighting asset; you're purchasing a ticking time bomb. This article will dissect the science of thermal management, moving beyond marketing claims to reveal the core engineering that separates a reliable, long-lasting solar light from one destined for an early grave.

The Enemy Within: Why Heat is the Silent Killer of Integrated Solar Lights

In a tightly sealed, IP66-rated enclosure, heat doesn't just dissipate; it accumulates. This trapped thermal energy launches a multi-front assault on the three most critical?and expensive?components of the system, starting a domino effect of degradation.

1. The Triple Threat to Longevity

Heat's attack is systematic. First, it targets the LED chips. For every 10�C increase in junction temperature above its optimal range, an LED's lifespan (L70) can be slashed by as much as 50%. This isn't just a theoretical number; it's the real-world reason why a poorly designed light appears dim and fails years ahead of schedule. Next, the lithium battery, the system's heart, suffers irreversible capacity loss when consistently operated above 45�C (113�F). This leads to shorter autonomy, reduced cycle life, and in worst-case scenarios, a dangerous condition known as thermal runaway. Finally, the MPPT controller, the system's brain, experiences accelerated aging of its sensitive electronic components, like capacitors, leading to reduced efficiency and eventual failure.

2. The Climate Multiplier: From Bad to Worse

These challenges are magnified in extreme climates. In the scorching heat of the Middle East or Sub-Saharan Africa, ambient temperatures can exceed 50�C (122�F). The black body of the luminaire absorbs intense solar radiation, pushing internal temperatures to a staggering 80-90�C. In humid tropical regions, the lack of significant temperature drops at night means the components never get a chance to cool down, leading to relentless thermal stress 24/7. These environments are the ultimate proving ground for thermal design, where inferior products inevitably fail.

The Blueprint for Coolness: Advanced Dissipation Technologies in 2025

Countering this thermal assault requires a multi-layered engineering approach that integrates material science, structural design, and intelligent component layout. Simply bolting on a larger heatsink is an outdated tactic; today's leading solutions treat the entire luminaire as a holistic thermal system.

1. Material Science as the First Line of Defense

The foundation of effective thermal management is the choice of materials. High-purity ADC12 die-cast aluminum is the industry standard for luminaire housings, not just for its strength, but for its excellent thermal conductivity (around 96 W/mK). This allows the entire chassis to act as a giant heatsink, drawing heat away from the core components. Furthermore, the use of advanced Thermal Interface Materials (TIMs)?often graphene-infused pads?is critical. These materials fill microscopic air gaps between the LED board and the aluminum chassis, creating a seamless thermal bridge that dramatically improves heat transfer efficiency compared to standard silicone grease.

2. Structural Design for Passive Airflow

An ingenious structural design can turn a sealed box into a self-ventilating system. One of the most effective techniques is the "chimney effect" or passive convection cooling. This involves designing internal channels that allow hot air to rise and exit through discreetly placed, IP-rated vents, while drawing cooler air in from below. This continuous, passive airflow can reduce internal operating temperatures by 10-15�C without compromising the light's waterproof integrity. The aerodynamic shape of the housing also plays a role, maximizing cooling from natural wind.

3. Component Isolation and Heat Spreading

Intelligent interior layout is crucial. Best-in-class designs physically separate the primary heat sources. The battery pack, which is highly sensitive to heat, is often placed in its own isolated compartment, shielded from the heat generated by the LED driver and chips. This prevents the battery from being "cooked" by the other components. This separation strategy ensures each part operates closer to its ideal temperature range, extending the life of the entire system.

The Long Game: How Smart Thermal Design Rewrites the TCO Equation

For a project manager or a government procurement officer, the initial purchase price is only a fraction of the story. A decision that ignores thermal management will inevitably lead to an explosive increase in the Total Cost of Ownership (TCO) due to maintenance, replacement, and reliability issues.

1. The Ripple Effect of Premature Failure

Let's quantify the impact. A light with poor thermal management might see its battery fail in 3 years instead of the expected 7-8 years. For a project with 500 lights, this means you are suddenly faced with the massive logistical and financial burden of replacing 500 batteries four years ahead of schedule. Add to this the cost of sending crews to diagnose and repair flickering or dead lights, and the initial "savings" on a cheaper product are quickly erased. This doesn't even account for the cost of reputational damage when a newly installed lighting system proves unreliable.

2. De-risking Your Investment in Harsh Climates

In projects for remote communities or critical infrastructure, reliability is not a feature?it's the mission. For an NGO coordinator, a lighting system that fails in a rural African village due to overheating represents a broken promise and a waste of donor funds. For a facility manager securing a large industrial park, unreliable lighting is a direct security threat. Investing in a product with proven, superior thermal management is a direct investment in project success and risk mitigation. It ensures the light delivers its intended social or security benefits for its entire projected lifespan.

Conclusion: From a Numbers Game to an Engineering Mindset

The conversation around integrated solar street lights must evolve. We must move past a superficial focus on watts and lumens and embrace a deeper understanding of the engineering that enables long-term performance. In the world of all-in-one solar lighting, heat is the ultimate arbiter of quality and value.

An effective thermal management system is not a luxury; it is the core technology that underpins every other performance metric?from lumen maintenance and battery lifespan to overall system reliability. By asking critical questions about material choices, structural cooling design, and component isolation, you shift from being a simple buyer to a savvy investor. You ensure that your project is built on a foundation of robust engineering, ready to withstand the toughest conditions and deliver reliable, efficient lighting for years to come.

Ready to Engineer Failure-Proof Solar Lighting Projects?

Don't just buy a light; invest in longevity. Contact the nfsolar team for expert Project Consultation and Product Inquiries. Let us help you specify solar lighting solutions built to thrive in the world's toughest conditions.

Website: www.nfsolar.net

Email: cocowang@novafuture.net

WhatsApp: +8613013537907

留言