The All-in-One Powerhouse: A Technical Deep-Dive into China's Integrated Solar Street Lights

- coco wang

- 2025年10月1日

- 讀畢需時 5 分鐘

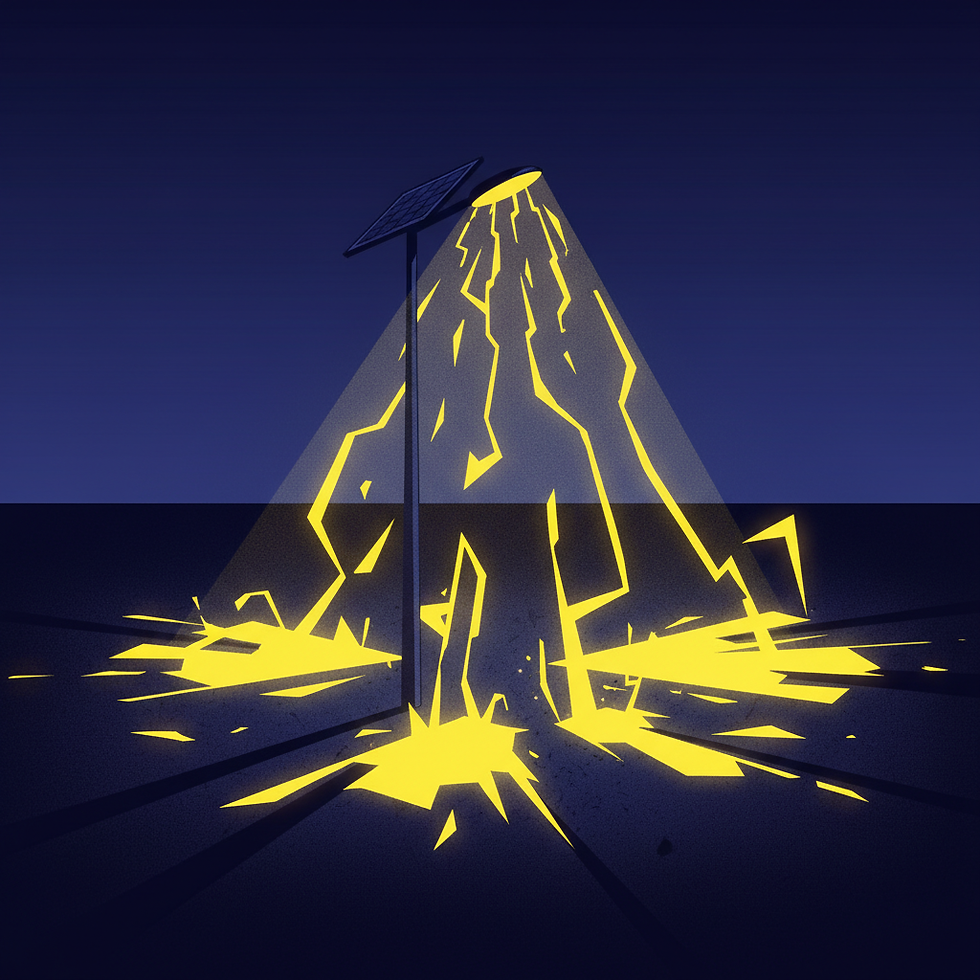

In the world of solar lighting, the integrated solar street light has rapidly evolved from a niche novelty to a dominant force. For project managers, engineers, and procurement officers, sourcing these units from China presents a landscape of immense opportunity?and significant technical complexity. The sleek, all-in-one chassis promises simplicity, but true long-term value lies hidden within its design philosophy, manufacturing precision, and material science.

This is not another surface-level overview. This is a deep-dive into the core engineering principles that separate a high-performance, reliable integrated system from a low-cost imitation destined for early failure. We will deconstruct these units to understand not just they are, but they achieve their performance, and what their ultimate limits are. This guide provides the technical framework you need to evaluate and specify these solutions with confidence.

The Integrated Advantage: More Than Just a Pretty Case

The move from traditional, modular solar lighting systems to integrated designs is one of the most significant shifts in the industry. This change is rooted in a philosophy of system synergy, where every component is designed to work in concert, creating a whole that is far greater than the sum of its parts.

The Power of Synergy: Unlocking Peak System EfficiencyIn a modular system, the solar panel, battery, controller, and LED fixture are often sourced from different manufacturers and cobbled together. An integrated design forces a holistic approach. The MPPT controller's charging algorithm is perfectly tuned to the specific LiFePO4 battery pack's voltage and capacity, while the LED driver's output is optimized for the luminaire's thermal properties. This eliminates guesswork and component mismatch, ensuring that every watt of solar energy is harvested, stored, and converted into light with minimal loss. It's the difference between a custom-tailored suit and an off-the-rack compromise.

A Project Manager's Dream: Slashing Installation Time and ComplexityConsider the on-site logistics of a modular system: mounting a heavy solar panel, wiring a separate battery box, connecting the controller, and finally, installing the luminaire. This process is labor-intensive, time-consuming, and introduces multiple potential points for installation error. An integrated unit transforms this ordeal into a simple, two-step process: mount the fixture on the pole and turn it on. For large-scale municipal or commercial projects, this reduction in labor costs and installation time can translate into tens of thousands of dollars in savings and significantly shorten project timelines.

Built to Endure: Why Fewer Parts Mean Fewer HeadachesEvery external cable, connector, and separate enclosure is a potential failure point?an entry for water ingress, a target for corrosion, or a temptation for vandals. By consolidating all critical components into a single, sealed, and robust chassis, an integrated design drastically reduces its vulnerability. This inherent simplicity doesn't just improve reliability; it fundamentally lowers the long-term maintenance burden, a critical factor for facility managers and municipal authorities focused on Total Cost of Ownership (TCO).

Inside the Dragon's Factory: The Manufacturing Edge

The theoretical advantages of an integrated design are only realized through manufacturing excellence. China's sophisticated production ecosystem allows for a level of process optimization and quality control that is crucial for the performance and durability of these compact, high-tech systems.

The Art of the Cell: A-Grade LiFePO4 and Automated SortingThe battery is the heart of the system. Leading manufacturers don't just buy battery cells; they manage a rigorous supply chain. This involves sourcing only A-grade LiFePO4 cells from top-tier producers. Before assembly, every single cell undergoes automated testing and sorting based on its precise voltage and internal resistance. This meticulous process ensures that every cell in a battery pack is perfectly matched, preventing the common failure mode where a single weak cell degrades the performance and lifespan of the entire pack.

Precision Optics: From Molten Polycarbonate to a Perfect BeamAn integrated light's ability to effectively illuminate a road or parking lot depends entirely on its lens. Advanced manufacturing involves in-house optical design and injection molding of high-transmission polycarbonate (PC) lenses. This allows for the creation of highly specific light distribution patterns (e.g., IES Type II or Type III) that maximize illuminance on the target area while minimizing light pollution and glare. It's a process where microscopic precision in the mold translates directly to superior real-world performance.

The Unseen Guardian: Advanced Battery Management Systems (BMS)The BMS is the onboard brain protecting the battery investment. Sophisticated manufacturing integrates multi-layered safety protocols directly onto the circuit board. This includes cell-level balancing during charging, protection against over-voltage, under-voltage, short circuits, and?most critically?high-temperature charging cut-offs. A well-engineered BMS is the key differentiator that allows a battery to safely achieve 2,000+ cycles, directly impacting the system's long-term financial viability.

Pushing the Limits: Materials and Engineering in Modern Designs

The performance ceiling of an integrated solar street light is defined by the materials used in its construction and the structural engineering principles that govern its design. These factors determine its ability to survive and thrive in the harshest outdoor environments for a decade or more.

The Backbone of the Light: ADC12 Aluminum and Thermal ManagementHeat is the enemy of both LEDs and batteries. The chassis of a premium integrated light is not just a housing; it's a sophisticated heat sink. The use of die-cast aluminum alloys like ADC12 is standard, prized for its excellent thermal conductivity and corrosion resistance. However, the performance limit is defined by the engineering of the heat sink itself?the surface area, fin design, and airflow channels that promote passive cooling. Effective thermal management is what allows the LED chips to maintain high luminous efficacy and a long L70 lifespan, even in scorching hot climates.

Surviving the Storm: Wind Tunnel Testing and Structural IntegrityFor a municipal procurement officer, public safety is non-negotiable. The performance limit of an integrated design is often tested by extreme weather. Top-tier manufacturers validate their designs through wind load analysis and sometimes even physical wind tunnel testing. This ensures the structural integrity of the housing and the mounting bracket can withstand hurricane-force winds. This isn't just about durability; it's about mitigating risk and ensuring the product is a safe, long-term public asset.

The IP66 Promise: What It *Really* Takes to Keep Water and Dust OutAny manufacturer can claim an IP66 rating, but the engineering to reliably achieve it is complex. It involves the use of high-grade, UV-resistant silicone gaskets instead of cheap foam. It requires meticulous design of interlocking seams and pressure-equalizing vents that allow the unit to breathe without ingesting moisture. For an engineer evaluating products, demanding details on gasket material and enclosure design is a critical due diligence step to verify that the IP rating is a reflection of robust engineering, not just a hopeful label.

Conclusion: From a Black Box to a Clear Choice

An integrated solar street light from China should not be treated as a commodity or a simple ?black box.? It is a densely engineered system where advantages in design, precision in manufacturing, and quality of materials converge to create a powerful, reliable lighting solution.

To make a truly informed decision, you must shift your evaluation from specifications on a datasheet to the engineering philosophy behind them. Ask the tough questions: How are your battery cells sorted? What is your heat sink's thermal resistance? How do you validate your IP rating? By understanding the technical depth behind the all-in-one concept, you can confidently select a product that delivers not just on the promise of simplicity, but on the expectation of long-term performance and value.

Ready to Illuminate Your Project with Confidence?

Don't just buy a light; invest in a solution backed by superior engineering. Connect with the specialists at Novafuture Tech for expert guidance on your next solar lighting initiative.

Website: www.nfsolar.net

Email: cocowang@novafuture.net

WhatsApp: +8613013537907

留言