Your Solar Lights Are Secretly Rusting Away. Here?s the Armor You Didn't Know They Needed.

- coco wang

- 2025年10月6日

- 讀畢需時 5 分鐘

An Expensive Oversight: Why We Must Talk About Materials First

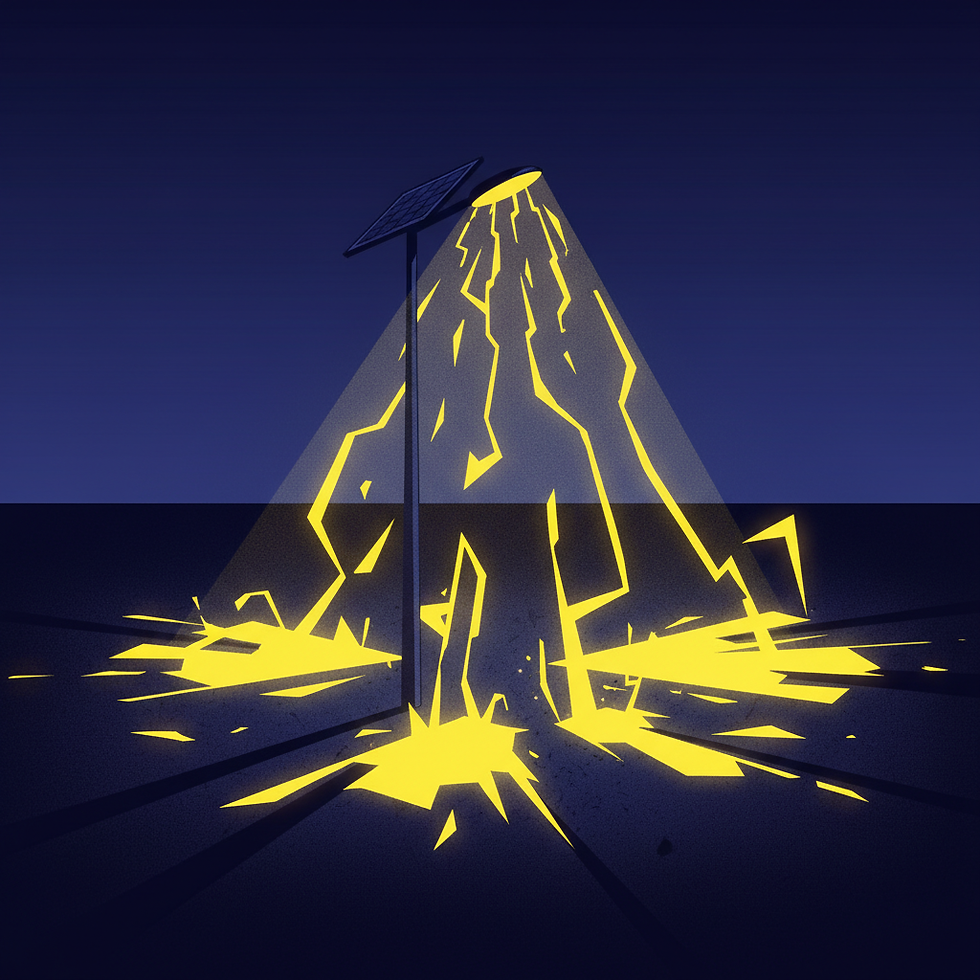

Imagine this: a project manager oversees the installation of hundreds of solar street lights for a new coastal highway. For the first year, they are a beacon of progress. But by year two, subtle rust spots appear on the poles. By year three, flickering lights and outright failures begin, leading to angry calls and costly maintenance dispatches. The culprit isn't a faulty battery or a bad LED chip. It's a silent killer that was specified on day one: the material itself.

In the world of infrastructure projects, focusing solely on lumens, watts, and battery capacity is a strategic error. The long-term success or failure of a solar lighting installation often hinges on its physical resilience?its 'invisible armor.' For project managers, engineers, and municipal officers, understanding the science of materials and coatings isn't a minor detail; it's the foundation of a reliable, long-term investment. This article will equip you with the technical knowledge to look beyond the spec sheet and evaluate the true durability of a solar street light.

1. The Anatomy of Failure: Deconstructing Environmental Attacks

Before we can appreciate the armor, we must understand the weapons it's designed to defeat. A solar street light is in a constant battle with its environment, facing a multi-front assault that degrades lesser materials with surprising speed.

The Corrosive Creep: Salt Spray in Coastal and De-Icing RegionsFor projects near the ocean or in areas that use road salt in winter, this is enemy number one. Airborne salt particles create a highly corrosive electrolyte solution when mixed with moisture, aggressively attacking steel and low-grade aluminum. This isn't just a surface issue; it's an electrochemical reaction that can compromise structural integrity from the inside out.

The UV Assault: How Relentless Sun Degrades More Than PaintUltraviolet (UV) radiation doesn't just fade paint. It breaks down the molecular bonds in polymer-based materials and coatings, a process called photodegradation. This leads to chalking, cracking, and a loss of protective properties, exposing the underlying metal to the elements and creating an entry point for corrosion.

The Chemical Cocktail: Industrial Pollutants and Acid RainIn industrial zones or areas with high air pollution, rainwater can become acidic, containing sulfur and nitrogen compounds. This chemical brew actively eats away at protective coatings and can accelerate the corrosion of the metal structure, significantly shortening the product's operational life.

The Sandblast Effect: Abrasion in Desert EnvironmentsFor installations in arid or desert climates, wind-blown sand and dust create a constant abrasive effect. This slow, steady 'sandblasting' can wear away protective coatings, exposing the bare metal to extreme temperature swings and the occasional corrosive morning dew.

2. The 'Invisible Armor': Breakthroughs in Materials and Coatings

Choosing the right defense requires understanding the technology behind it. Modern solar street lights leverage advanced material science to create a robust, multi-layered defense system that goes far beyond a simple coat of paint.

Beyond Basic Steel: The Rise of Advanced Aluminum AlloysWhile galvanized steel (like Q235) is a traditional choice, it's heavy, making installation more costly and labor-intensive. The real innovation lies in aluminum alloys. However, not all aluminum is created equal. Die-cast aluminum (like ADC12) is common but can be brittle. The superior choice for structural components is high-grade extruded aluminum, such as 6063-T6. This alloy offers an excellent strength-to-weight ratio and, more importantly, naturally forms a passive oxide layer that provides inherent corrosion resistance.

The Multi-Layer Defense: Deconstructing High-Performance CoatingsA premium coating is not a single layer; it's an engineered system. Think of it like dressing for a blizzard: you need a base layer, an insulating layer, and a waterproof shell. A high-performance coating system works similarly:

Layer 1: The Primer Coat. Often a zinc-rich epoxy or phosphate conversion coating, its primary job is to create a tenacious bond with the metal substrate and offer sacrificial cathodic protection.

Layer 2: The Intermediate Coat. This is the bulk of the protection, typically a high-build epoxy that provides chemical resistance and seals the primer.

Layer 3: The Topcoat. This is the visible layer and the first line of defense against UV and weather. Polyester powder coatings are good, but fluorocarbon (PVDF) coatings offer superior color retention and resistance to UV degradation, making them the gold standard for long-term projects.

Sealing the Gaps: Why IP67/IP68 Ratings Are Mission-CriticalThe most advanced material is useless if water and dust can get inside the luminaire or battery compartment. An IP (Ingress Protection) rating is a verified measure of this seal. An IP67 rating means the enclosure is completely dust-tight and can be submerged in 1 meter of water for 30 minutes. This isn't just about surviving a rainstorm; it's about ensuring that corrosive humidity and fine dust particles cannot reach the sensitive electronics and battery terminals, a critical factor for long-term reliability.

3. The Procurement Gauntlet: How to Specify and Verify True Durability

As a discerning buyer, you must move from being a price-taker to a quality-specifier. You can command project success by demanding the right information and proof from your suppliers.

Reading Between the Lines of a DatasheetDon't accept vague descriptions. Your technical specification documents should demand clarity:

Instead of "Aluminum Alloy," specify "Minimum 6063-T6 Grade Extruded Aluminum for Pole and Housing."

Instead of "Powder Coated," demand "Minimum 80?m thickness Polyester Powder Coating System applied over a phosphate conversion layer."

Ask for the specific grade of all hardware. A beautiful aluminum pole held together with cheap galvanized steel bolts will show rust streaks in months. Demand SUS304 or SUS316 stainless steel fasteners.

The Acid Test: Demanding Proof with Third-Party ReportsClaims are meaningless without evidence. For any serious project, request the following test reports:

Salt Spray Test (ASTM B117): This is a critical test for corrosion resistance. A 1000-hour rating is a strong benchmark for marine-grade or high-risk environments. It?s a tangible way to compare the performance of different coatings.

UV Accelerated Aging Test (ASTM G154): This test simulates years of sun exposure in a matter of weeks, providing crucial data on how well a coating will resist fading and degradation.

IP Rating Test Report: Always ask for the third-party lab report that verifies the claimed IP rating. This ensures the product was tested to the standard, not just self-declared.

A Physical Inspection: The Final CheckWhen evaluating samples, look for signs of quality. Is the coating smooth and uniform, even on edges and corners? Are the seals and gaskets well-fitted? Are the fasteners made of stainless steel? Small details often reveal the true manufacturing philosophy of a supplier.

Conclusion: From Price-Tag to Life-Cycle Value

The conversation around solar street lights must evolve. Shifting the focus from the initial price tag to the total cost of ownership reveals that investing in superior materials is one of the most financially sound decisions a project owner can make.

A well-engineered physical structure?the 'invisible armor'?doesn't just prevent rust. It protects the entire investment. It ensures the high-performance LEDs, intelligent controllers, and advanced batteries you paid for can deliver on their promise for their full intended lifespan. By arming yourself with the right technical questions and demanding verifiable proof of quality, you transition from simply buying a light to investing in a decade of reliable, uninterrupted performance.

Don't Let Corrosion Compromise Your Project. Build Its Armor.

The environmental challenges for your project are unique. The protection for your solar lighting should be, too. Don't leave long-term durability to chance.

Contact the expert team at Novafuture Tech (nfsolar) for a comprehensive project consultation. We'll help you navigate the complexities of material science and specify a solution engineered to thrive in your specific environment.

Website: www.nfsolar.netEmail: cocowang@novafuture.netWhatsApp: +8613013537907

留言